Primary and secondary chilled water systems

Hydronic systems in commercial HVAC plants can be configured in different ways. HVAC systems can be pumped using a primary, primary-secondary, primary-secondary zone, or a primary-secondary-tertiary system. Although variations exist in the implementation of the above systems, their working principles largely remain unchanged. As chilled water pumping can use 6-12 % of an HVAC plant’s annual electricity consumption, choosing the right chilled water pumping scheme is essential in improving energy efficiency.

In primary chilled water systems, only one set of pumps exist which distribute chilled water from chillers to the entire building.

In primary-secondary chilled water systems, 2 sets of pumps handle the distribution of chilled water. Primary pumps are tasked only with maintaining constant flow within the primary chiller circuit. The secondary pumps (usually fitted with VFDs) maintain variable flow as per real-time load conditions in the secondary chilled water circuit. As flow can be adjusted according to the required load, these configurations result in improved energy efficiency.

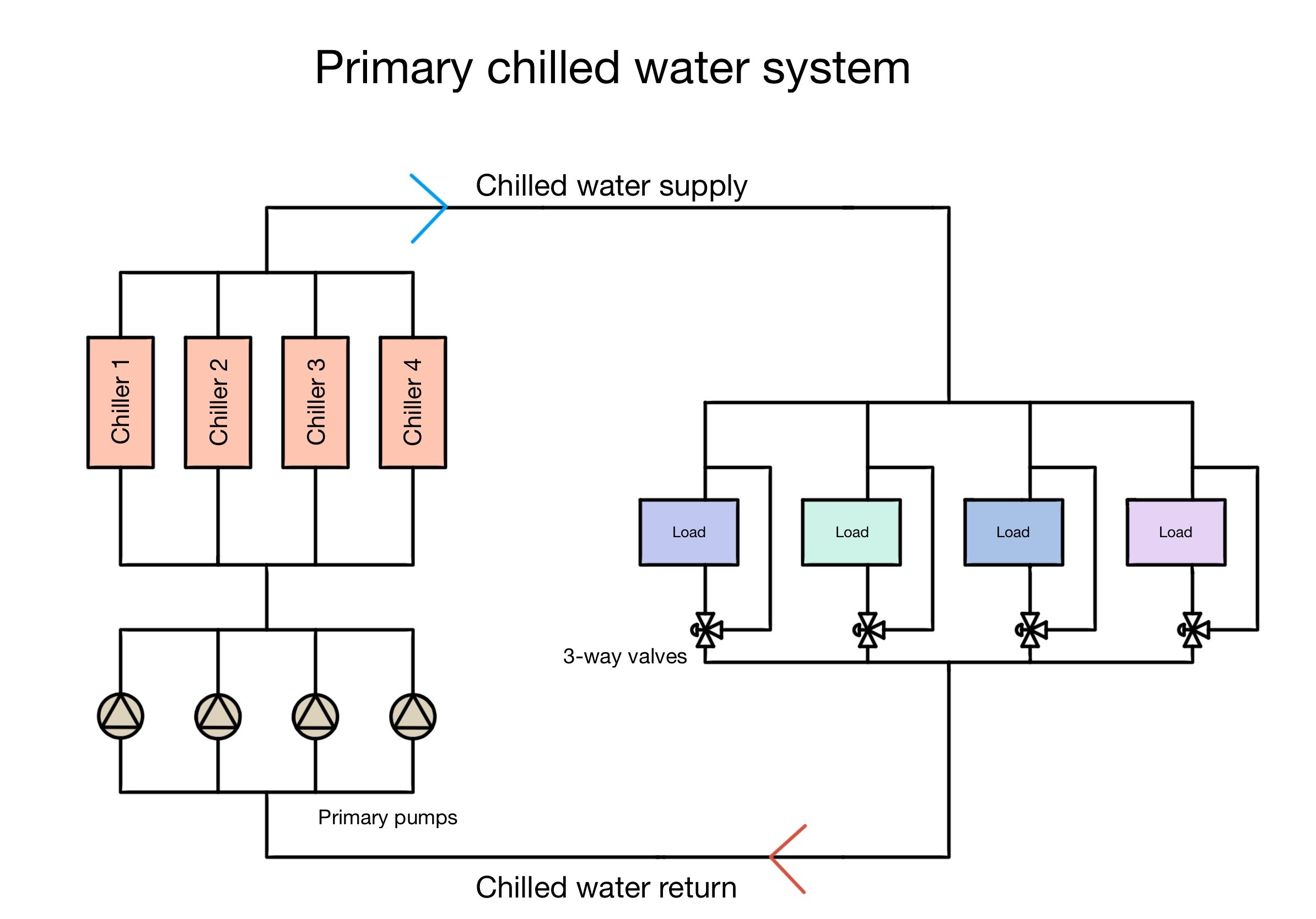

1. Primary chilled water system

In a primary hvac pumping system, a number of pumps distribute a fixed amount of water from the chillers to the building constantly. In a constant flow system, flow rate is not changed in response to varying load but temperature or Delta-T is. Delta-T is the numerical difference between the chilled water supply and return setpoints.

Chillers produce a constant supply of chilled water at the set temperature. Primary pumps distribute this water at a constant flow rate. The Delta-T is in effect controlled by the 3-way valves located at the loads (AHUs, FCUs etc.) which divert some amount of chilled water during part-load conditions.

If the return water temperature is not high enough, this can result in low Delta-T syndrome.

2. Primary-Secondary chilled water system

In a primary-secondary HVAC pumping system, 2 hydraulically separate chilled water circuits are present.

The primary circuit has low head primary pumps which typically maintain a constant flow rate through chillers. The secondary circuit has high head secondary pumps which maintain flow through loads (AHUs, FCUs, etc). Secondary pumps are usually fitted with VFDs so that they may vary flow through the secondary circuit as per load conditions. This results in better control and hence better overall system efficiency.